Answer these four questions and

FIND THE IDEAL FIREWOOD PROCESSOR FOR YOU

.jpg?width=2000&name=Hakki-Pilke-55-Pro_10%20(7).jpg)

About Hakki Pilke

Hakki Pilke has sold over 30,000 units in over 35 countries. In the 1990s, model 1X37 revolutionized the firewood industry becoming the world’s most sold firewood processor. Today the Hakki Pilke brand is known for its excellent after-sales services and state of the art performance and reliability.

HakkiCutTM cutting interface makes processing fast and ergonomic with press of a button. AC10 automatic chain tensioner doubles the life of saw chain parts and allows chain replacement without tools. HakkiSplitTM 3-speed splitting system provides 3-4 second cycle times for the hardest woods.

See official Hakki Pilke Website & Brand video: Excellence in Firewood Processing Manufacturing

Learn more about the best firewood processors built in the world and Join the Winning Team!

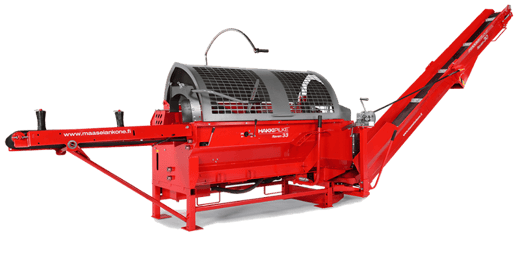

Semi-automatic firewood factory with innovative functions

55 PRO

22 IN

24 IN

24-WAY

The Hakki Pilke 55 Pro brings the firewood processing to the modern age with innovative and automatic functions. With the new HakkiMultiBlade™you can split up to 24 pieces and then easily change to 8 pieces in only seconds. The automatic hydraulic height adjustment of the splitting blade ensures consistent high-quality firewood even when the diameter of the logs varies. The monitoring system is collecting important data from machine’s productivity and processes.

Features: Data monitoring system, Half-stroke splitting, HakkiCutTM, HakkiSplitTM, AC10 automatic chain tensioner, oil cooler, massive splitting force, no v-belts, small maintenance.

Watch video: 55 Pro

The Hakki Pilke 55 Pro was designed for effective professional firewood processing in close cooperation with firewood professionals around the world. The innovative functions of 55 Pro ensures superior performance in all conditions and situations. It demolishes 55 cm (22") logs of hardwood to high quality firewood with 40 tons (44 US tons) splitting power and high-performance hydraulic functions.

The Hakki Pilke 55 Pro brings the firewood processing to the modern age with innovative and automatic functions. With the new HakkiMultiBlade™ you can split up to 24 pieces and then easily change to 8 pieces in only seconds. The automatic hydraulic height adjustment of the splitting blade ensures consistent high-quality firewood even when the diameter of the logs varies. The system has an innovative sensor that measures the diameter of each log and adjusts the splitting blade height accordingly to get optimal results.

The 55 Pro has a modern data monitoring system with easy-to-use monitor screen. The monitoring system is collecting important data from machine’s productivity and processes. You get a real-time information about processed volumetric measurements, hours of operation, splitting method and safety covers. User can easily change the wanted length for the firewood from the monitor. The measuring device moves automatically to the correct position based on the selected length. The plate can be driven manually forward or backward from the monitor’s buttons.

The productivity level of 55 Pro is unbeatable with the delay-free HakkiSplit™ splitting system with half-stroke function for making short firewood faster. You can choose the splitting to return after full, half or one-third of the stroke. The log landing plates ensure that even the shortest cut logs land neatly into the splitting groove.

The 55 Pro has automatic greasing system that pumps at standard intervals, which saves maintenance time. The standard equipment’s also include HakkiCut™ sawing interface, AC10 automatic chain tensioner and electric automatic chain oil lubrication.

50 PRO

19 IN

24 IN

16-WAY

Heavy-duty processor for commercial sized operations and top grade firewood quality.

Features: HakkiCutTM, HakkiSplitTM, AC10 automatic chain tensioner, oil cooler, massive splitting force, no v-belts, small maintenance.

Watch video: 50 Pro

Hakki Pilke 50 Pro was designed in close cooperation with international firewood professionals and tested with the hardest wood species to ensure viability as a professional-grade machine with superior performance in all conditions. Technologically advanced cutting system with market’s fastest splitting cycle challenges heavy built circular saw processors.

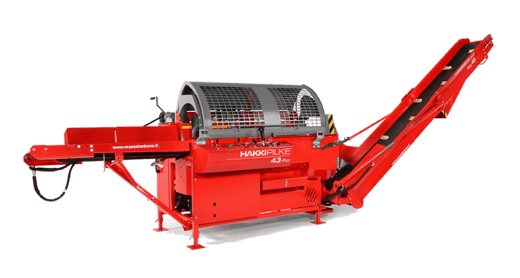

43 PRO

17 IN

24 IN

12-WAY

World’s best-selling professional class firewood processor with cycle time of 3.5 seconds and unbeatable productivity. Features: HakkiCutTM, HakkiSplitTM, AC10, oil cooler, infeed assistant, log landing plates, no v-belts, small maintenance

Watch video: 43 Pro

Over 150 units sold during the first 12 months after the launch in 2016, many customers processing over 1,500 cords of firewood annually. Highly reliable electric control system that minimizes the number of components requiring maintenance. Process logs with the press of only two buttons when infeed assistant is in use. Log landing plates ensure smooth processing every single cut. Very low overhead costs. Perfect weight ratio makes it very easy to move on site.

38 PRO

15 IN

24 IN

16-WAY

Simple to use high-speed machine with 3 second splitting cycle and the capacity to split the hardest woods into 8 pieces. Features: HakkiCutTM, HakkiSplitTM, AC10, no v-belts, small maintenance.

Watch video: 38 Pro

This machine boasts the easy push button controls and advanced cutting system to make it a top choice amongst producers. Extra features are scaled down to make it the number one choice among top producers looking for highest productivity with smaller investment. Weighing under 2,000 pounds the 38 Pro is moved easily with even small or compact tractors.

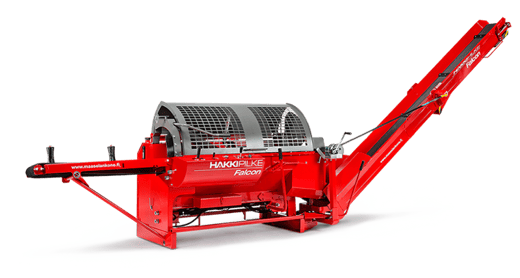

FALCON 37

14.5 IN

20 IN

6-WAY

With simple mechanics and hydraulic joystick the Falcon 35 is a perfect machine for small- and mid-sized firewood operations and home users. Falcon 35 boasts a 3-second splitting cycle and ergonomic one hand control.

Features: 2-speed splitting, fast hydraulic functions, no electrics, no v-belts, small maintenance.

Watch video: Falcon

Falcon is the modern version of the 1X37 which dominated the global firewood market from mid 1990s until late 2000s. Over 800 international Falcon 35 owners and non-existent spare parts demand proves it the perfect firewood processor for years of seasonal use and no problems.

RAVEN 33

13 IN

20 IN

6-WAY

Reliable and easy-to-use processor for smaller diameter logs. The machine’s direct drive hydraulics enable simultaneous functions with the effortless motions of the traditional operating lever. Processing firewood was never this easy!

Features: Hydraulic infeeding, Extremely safe, no v-belts, very low maintenance.

Watch video: Raven 33

The unique operating function of this low maintenance firewood processor ensures low investment cost and fast simultaneous operation of the splitter and saw. Robust structure makes it a firewood processor that lasts for generations to come.

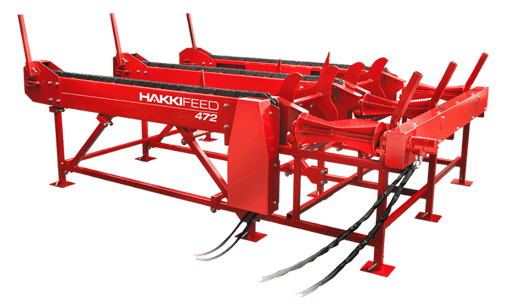

HAKKIFEED LOG TABLES

The sturdiest log decks designed for full control of logs of varying quality even when piled up in layers for greater efficiency. Log tables are easily extendable offering 2-3 times larger loading space than competitors. Fast chain movements and log separating features allow improved productivity of infeed operations. Watch video: HakkiFeed 472

HakkiFeed 470-series are designed for full control of awkward knotty and crooked logs. Choose 3-chained HakkiFeed 472 for longer logs and 2-chained HakkiFeed 471 with adjustable width for shorter logs. The low priced HakkiFeed 422 is perfect for smaller operations with varying log lengths and quality.

Hakki Pilke XL Conveyor

The Hakki Pilke XL Conveyor is available as optional equipment. You can complete and maximize the efficiency of your firewood factory by adding either the 6 m or 8 m XL Conveyor to the 55 Pro’s outfeed conveyor. The conveyor’s 60 cm (24") wide belt transports easily large amount of firewood and it has a cleaning system that separates the debris from the firewood. The XL Conveyor is also easy to remove from the machine and transport by its own tires for short distances.

firewood cleaning

All Hakki Pilke firewood processors are equipped with a standard debris cleaning outfeed conveyor that cleans most of the debris before it ends up in the firewood pile. Conveyors are pivoting for efficient filling of firewood sacks or truckloads. For industrial purposes, Hakki Pilke offers two firewood cleaning devices. Watch video: Cleaner & Roller

Hakki Pilke Roller is a stand-alone firewood cleaner to achieve the very best quality and debris free firewood. It is great for large quantities of firewood under the demand of daily use and can be used together with a front loader. Hakki Pilke Cleaner is a robustly built and height adjustable tumbler style cleaner equipped with a 10 feet integrated conveyor.

Firewood processors for all needs

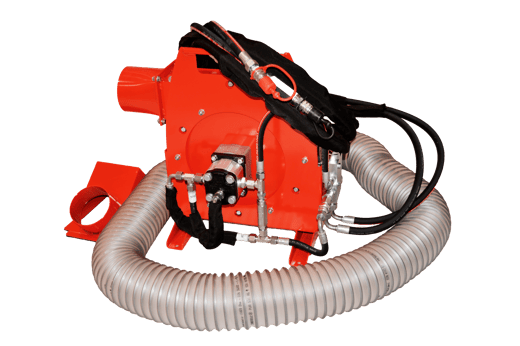

Advanced hydraulic design and compact size make Hakki Pilke firewood processors highly portable with low fuel consumption. Move the processor quickly with a small to mid-sized tractor or a skid steer and keep the operations clean with optionally installed saw dust blower.

Choose from multiple power options: PTO machines for tractors between 25 to 50 hp and Hakki Pilke Power Unit equipped with 21 to 35 hp petrol engine. Inquire for 3-phase electricity options for indoor use.